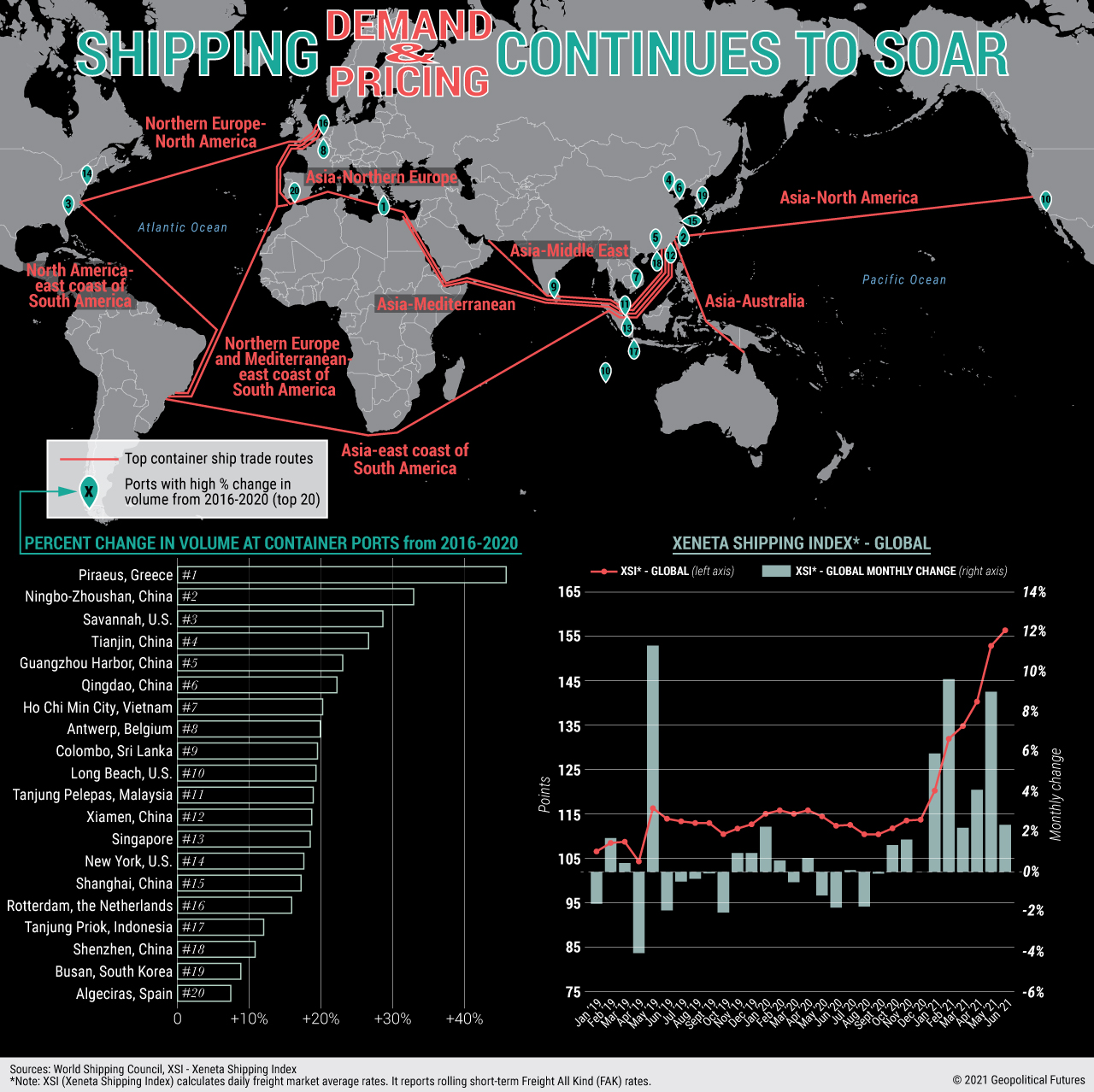

The epochal global supply chain snarl isn’t going away. The COVID-19 pandemic exposed widespread structural fragilities in the global trading system, first through production slowdowns and then, almost as quickly, a slingshot recovery in demand. This, along with labor shortages, left finely tuned logistics networks overwhelmed and off-balance. This is illustrated through unprecedented congestion at Western ports, where ships and (just as important) shipping containers have been stuck in pileups. Ships are waiting for berths. Shipping containers are waiting for truckers (facing a deep labor shortage) or space on railways (which are at capacity). Major exporters like China, then, have been stuck waiting unusually long times for ships and shipping containers to return. Countless other hiccups in supply chains near and far are further complicating the situation. The disruptions in supply, along with record shipping costs, are perhaps the foremost driver of inflation in many countries.

It’s anyone’s guess how long it will take to untangle this mess. There are simply too many single points of failure – each of which can affect a dozen more – for things to snap back to working order quickly. However the immediate situation plays out, though, there’s likely to be immense long-term implications as countries across the globe scramble to try to rewire the global trading system around their needs.